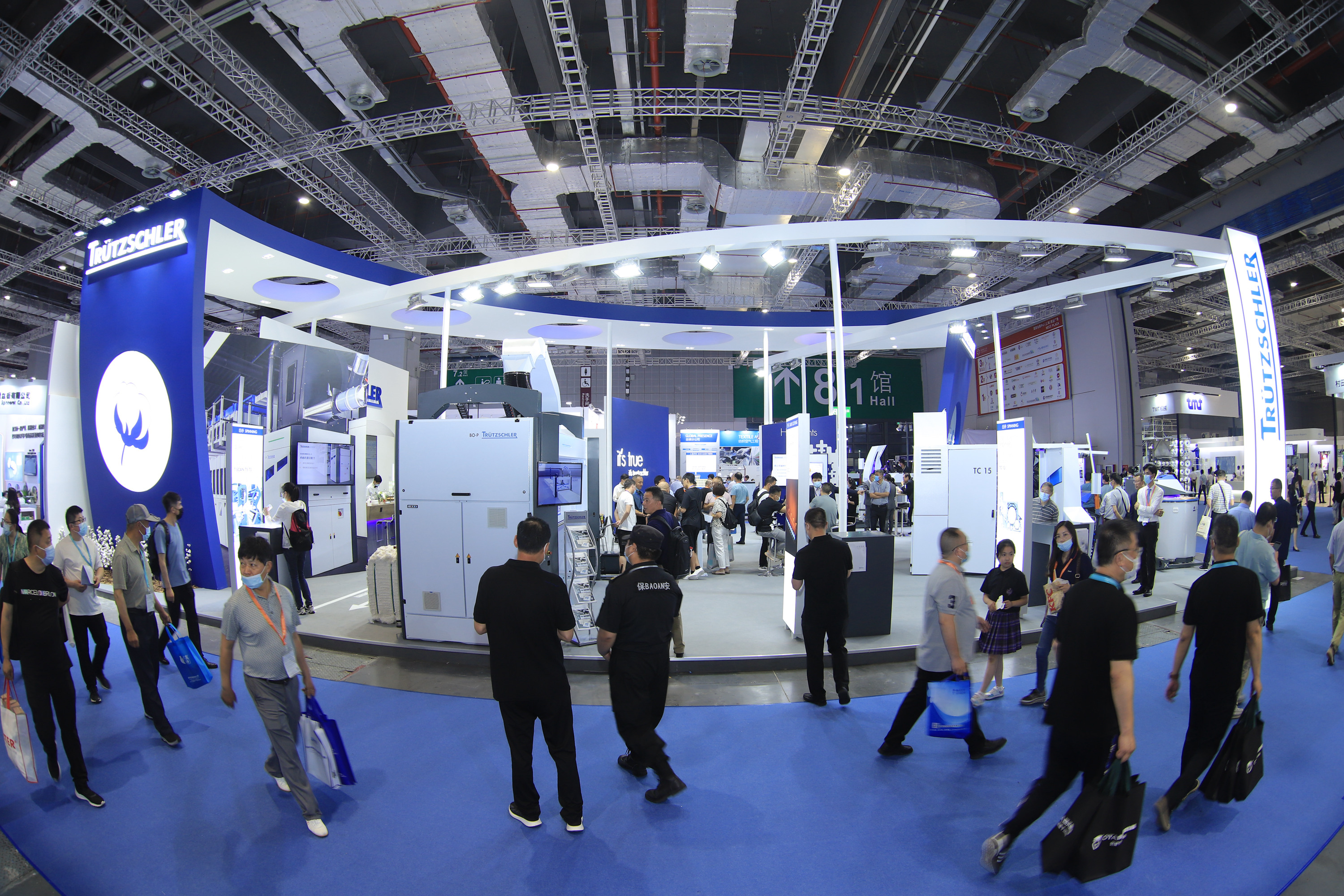

Legacy isn’t limited to a will or an inheritance, it is what a father gives his children in terms of support, wisdom, character, and faith. When it comes to handing over business, every father moulds his children with his best knowledge and wisdom. Nitin Spinners, Sudiva Spinners and Lagnam Spintex, all renowned spinning mills in India established by the fathers, are now looked after by their sons. Truetzschler is the one thing that is common in all three of these ventures.

Nitin Spinners goes places

Chairman R. L. Nolkha founded Nitin Spinners in 1992 as a launch pad for his son Dinesh, who had just completed his Chartered Accountancy. Later his younger son Nitin also joined the venture as an Executive Director. Starting with two open ends machines, Nitin Spinners stands tall with 3 lakh ring spindles, 3500 rotors, 63 knitting machines, 168 air-jet looms with 200 tonnes per day production of 5s to 80s yarn counts today. “We are a high quality manufacturer of yarn and do not believe in compromising quality on any parameter. We needed the best possible technology partner and Truetzschler perfectly fitted the bill”, remarks RL Nolkha. The relationship with Truetzschler began in 1992. Nitin Spinners currently has 142 Truetzschler cards in all their units. They ventured into blending with Truetzschler’s T-Blend. Dinesh Nolkha praised the blending technology and said, “It gives us more flexibility to produce different blends with the highest precision and lowest CV%.” By combining a sharp focus on sustainable profitability with innovative products, the father-sons trio have created a name for Nitin Spinners in more than 60 countries covering five continents where their yarn is exported.

Dinesh Nolkha, R. L. Nolkha & Nitin Nolkha

Sudiva Spinners’ success since 2006

J.C. Laddha has a vast experience in the textile industry since 1973. He already knew the advantages of Truetzschler machines as he was responsible in setting up and modernising the various units of RSWM Ltd. during his time at the company. In 2006 his son Varun Laddha returned from the USA after completing his higher studies. Given the choice between joining a company and starting his own company, Varun Laddha chose to set up his first venture – Sudiva Spinners – with the guidance of his father. The first-generation entrepreneur explained, “Out of ring spinning and open end, I opted for OE process as my first project because it required relatively lesser capital investment. However, to get the best quality yarn with highest productivity, we opted for the best in-class machinery from Truetzschler”. At present, Sudiva Spinners has about 74,000 spindles and 2,208 rotors. The latest project which was commissioned in 2018 was one of the first spinning unit in India to opt for the latest TC15 Cards with T-Move and JUMBO CANS. Today, the unit hosts 59 Truetzschler cards. By focusing on product development and taking calculated risks, Mr. Varun has ensured that Sudiva Spinners not only dominates the domestic yarn market, but is an impeccable supplier of yarn to more than 32 countries around the globe.

J. C. Laddha & Varun Laddha

Langam Spintex takes pride in producing high quality yarn

Mr D.P. Mangal was the Executive Director of Rajasthan Spinning and has an experience of more than 40 years in the textile industry. Together with his son, Anand Mangal, they founded Lagnam Spintex in 2011 with four open end machines having 1920 Rotors fed by Truetzschler machines. Since 2011, Anand Mangal has been working as Managing Director of the company responsible for production, marketing, purchase and administration of the existing textile facilities. From the beginning, Mr. Mangal was very clear to have the latest technology machines in his plant. It was no surprise that for their expansion in 2018, they opted for the latest TC 10 cards with T-Move and Jumbo Cans. According to Mr. Mangal, Truetzschler’s innovative concepts have provided them with greater benefits and improved process efficiencies. Presently, Lagnam Spintex has a production capacity of 35 tonnes per day, out of which 50 % goes for export with the yarn count ranging from 6 Ne to 30 Ne. Lagnam Spintex is one of the few spinning mills in the world to be certified by Uster for producing top-quality open-end yarn.

Anand Mangal & D. P. Mangal