We started delivering our new Truetzschler Draw Frame TD 10 to customers in India at the beginning of 2020 – and the response has been incredibly positive.

Since the market launch of the Truetzschler TD 10 in India, it has won approval from customers across this important market. The new model demonstrates superior performance when compared to competitors’ machines because it offers a unique range of advanced features that make it easy for mill operators to use and maintain.

Its SMART CREEL, for example, features motion sensors that improve the machine’s running performance and make it possible to detect missing slivers very quickly. On top of this, the independent SERVO CREEL offers precise adjustments for creel tension. The T-LED feature provides unique visualizations that help to keep machines running efficiently, while making it easier to monitor the operation.

Proven advantages for spinning mills across India

The draw frame is widely considered to be the quality center of a spinning mill – and our model TD 10 has proven its ability to further strengthen quality across a variety of different raw materials and processes. It has gained high levels of customer satisfaction because it empowers mill operators to achieve

faster delivery speeds, lower sliver U% and CV%, more reliable running behavior, and more stable and consistent performance. It also requires a lower parts inventory because it uses major electronics parts that are common in blow room and cards.

Our site in India is now delivering the Truetzschler draw frame TD 10 to spinning mills across the country, and giving them a powerful competitive advantage by improving productivity and yarn quality.

Check out the data below for more detailed insights into how the Truetzschler TD 10 offers clear advantages over models from other providers.

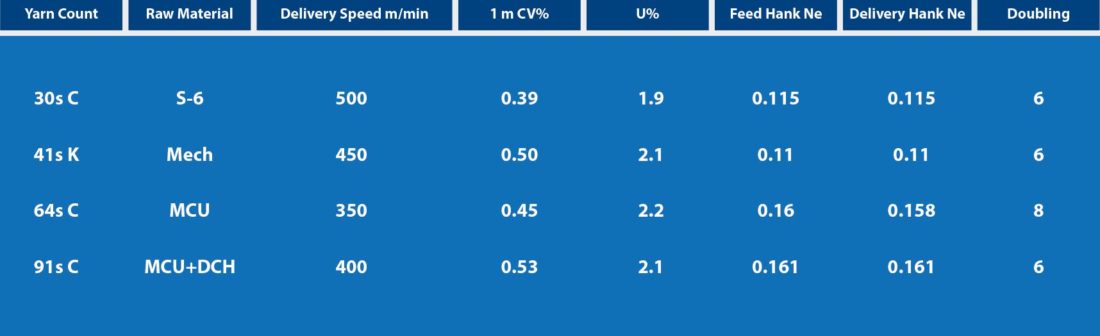

Performance on cotton application

This table shows the sliver quality parameters on the Truetzschler TD 10. In almost all cases shown, our machine offers a 25 to 30 percent higher delivery speed than earlier generations of draw frames from our competitors, while also achieving better yarn parameters.

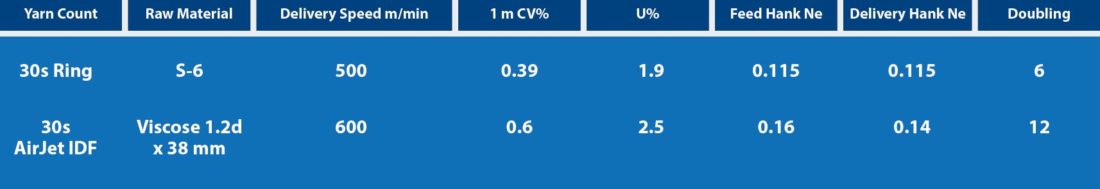

Performance on 100 percent viscose application

The Erode-Pallipalayam area of Southern India is an important production hub for 100 percent viscose yarn on ring spinning and air jet spinning systems. Truetzschler has a large installation base for all of our machines in this area. Recently, we supplied our new TD 10 draw frames to some of the region’s most widely respected mills – including Pallava Group, Arunachal Gounder, Mothi Spinning, and Kumaragiri Textiles. Pallava Group is using the TD10 in the new IDF VORTEX SPINNING process, the new process shortage with IDF for Airjet Spinning.

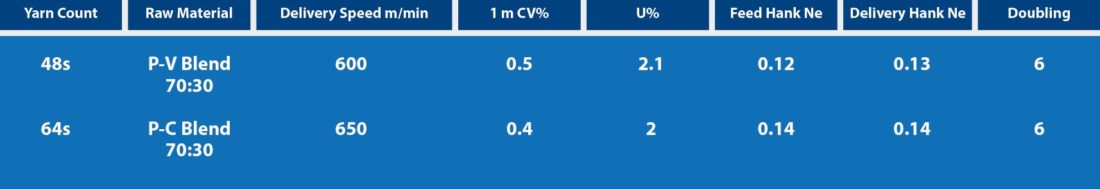

Performance on blend application

This table shows the sliver quality data when processing different blends.