And the winner is… Voith and Truetzschler Nonwovens! Together with the company Voith, we received the “Living Standard Award” from the Austrian Standards International. The Austrian competence centre for standards honored us for starting a standardization process for wet-laying and spunlacing machinery. Read on to learn more about the technology and our future plans.

From left to right: Herbert Haydn (Voith), Manfred Gloser (Voith), Egon Krätschmer (Voith), Christian Knörzer (Truetzschler), Thomas Kastler (Voith)

WL-what?

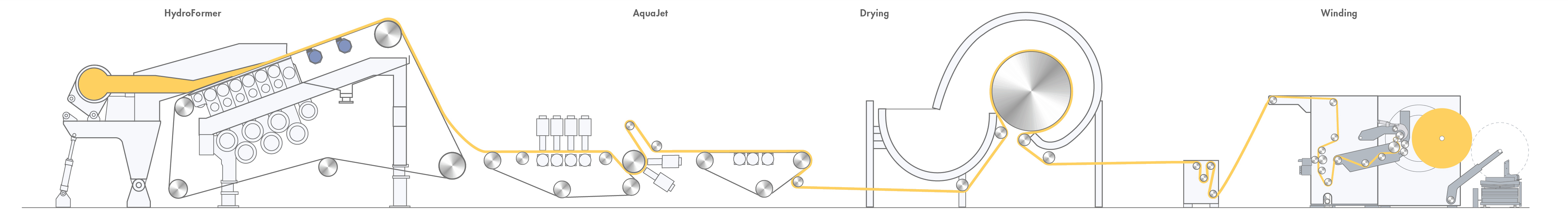

Ever heard of “wet-laying/spunlacing”, “WLS” or “wet-in-wet process”? Those terms refer to a nonwovens production process in which water plays a major role. As in paper making, web forming starts with a suspension of water and fibers. When passing over an inclined wire, the water drops off and a homogeneous fiber mat forms on the wire.

What stands behind the technology

Hydroentangling (or spunlacing) with high-pressure water jets is the technology for bonding the web. When the water jets hit the fiber mat, single fibers are moved and entangle with other fibers. The web becomes a strong nonwoven. Drying, finishing and winding turn the material into a roll ready for sale or for converting.

From old to new

Wet-laying of fibers is not a new invention – it is an „old“ paper making technology which has been adopted by nonwovens producers. According to The Fiber Year, wet-laying nowadays accounts for almost 7% – or 900.000 tons – of worldwide nonwovens production. Typical end products are cigarette paper, wall coverings, glass-fiber roofing materials, tea bags and coffee pads. Usually chemical binders glue the fibers together and thus bond the web. Wet-laying is a versatile web forming technology because it is suited for every fiber type dispersible in water.

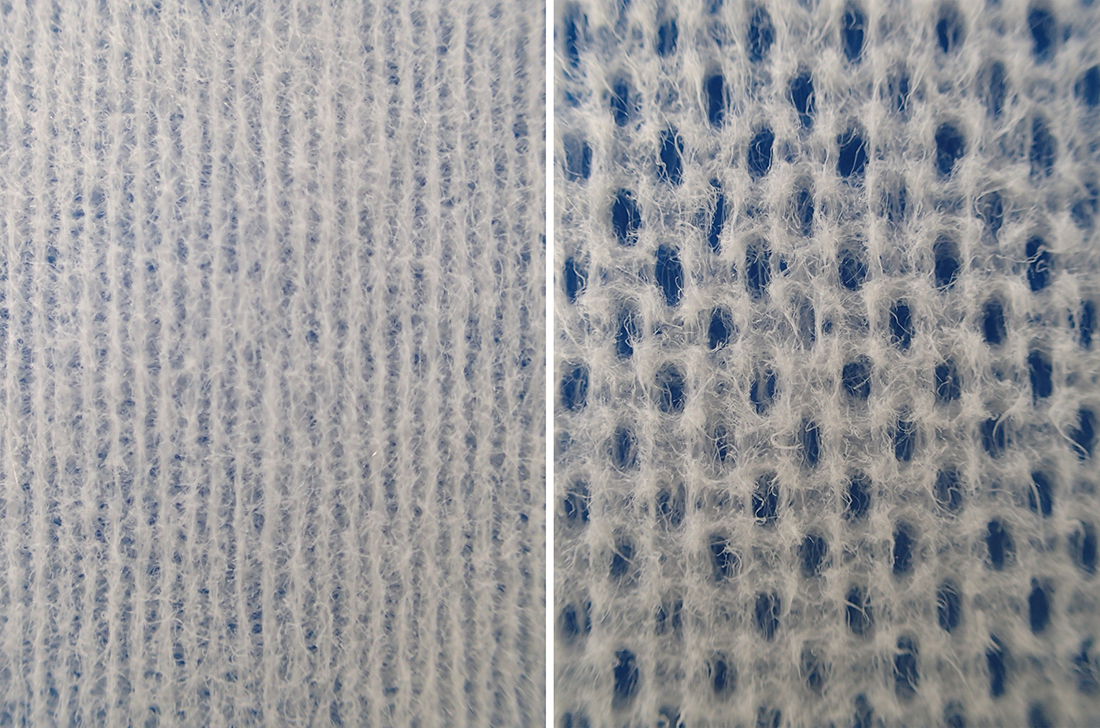

Macro shot of plain (left) and perforated (right) WLS nonwovens

A door-opening combination

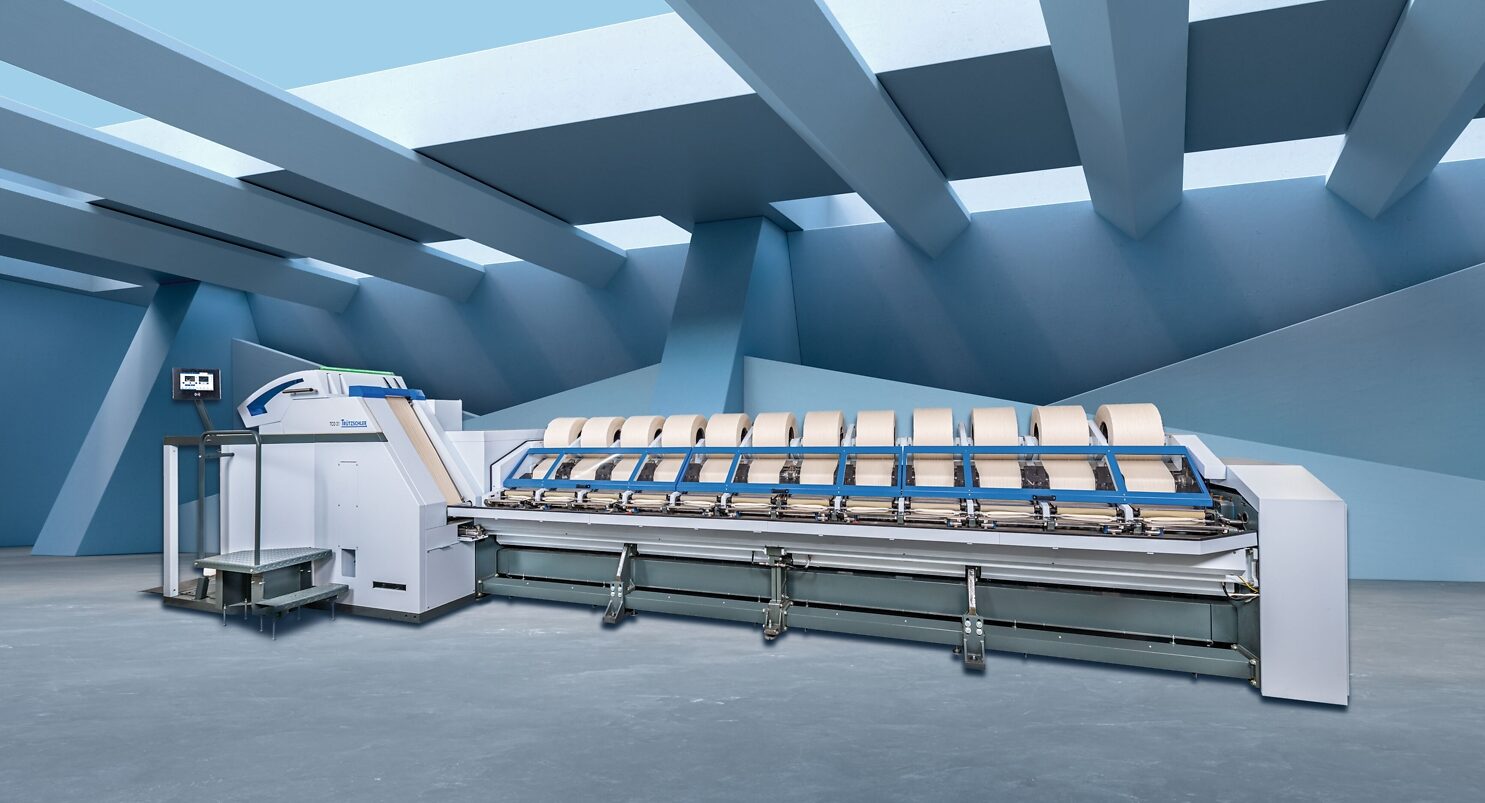

The combination with spunlacing opens a door to new applications. When Voith and Truetzschler Nonwovens teamed up in 2013, the whole WLS process chain became available under one roof. Work began with a lot of (successful) trials to make materials for flushable wipes. Today, the WLS technology has been sold to 5 producers worldwide with the latest line starting up in mid-2019.

A technology of our times

By developing the flushable wipes as the first application, the full potential of WLS became visible. It is a technology of our times: it is flexible in regard to fiber material and end products. It is a sustainable technology because there is almost no waste in the production process. And it makes “green” products if required: nonwovens made from pulp and cellulosic fibers are biodegradable and come from renewable resources. But these are all stories to be told later…

Not long ago Voith and Truetzschler Nonwovens again started trials in their 2 technical centers. Now it is about making standard (non-flushable) wipes…So stay tuned!