In cotton spinning, efficiency is a key factor. Every kilogram of raw material counts, not only for profitability but also for sustainability. This makes the first step in the process, cotton processing in the blow room, especially important. Here, fibers are opened, cleaned, and prepared for carding. During this stage, impurities and short fibers are removed to ensure high yarn quality. However, a considerable number of usable fibers often end up in the waste stream. On average, cotton spinning lines discharge 3 to 7% of blow room waste. For a mill processing thousands of tons annually, this translates into hundreds of tons of lost raw material and significant financial loss. The question is: How can mills recover these fibers and turn waste into value?

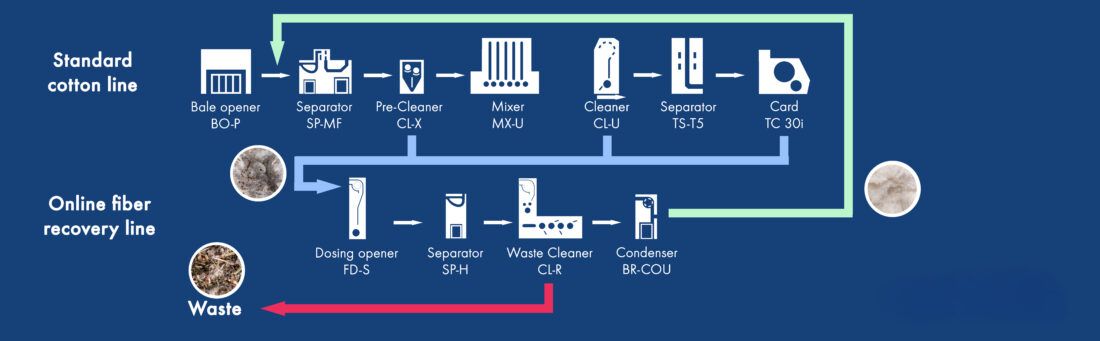

The solution: Trützschler Online Fiber Recovery Line

At Trützschler, our blow room lines are designed to minimize cotton waste from the very beginning. Through advanced technologies, we ensure that only a very small amount of residual waste remains after the cleaning process. And for this remaining waste, we go one step further: With the Trützschler Online Fiber Recovery Line, these fibers get a second chance. Our advanced system reprocesses blow room and card waste directly within the line. Waste is extracted, carefully cleaned, and can be fed back into the process. The result? Valuable fibers are recovered and reintegrated into production. Less waste, more value, and a smarter approach to cotton processing.

This unique solution can be easily retrofitted into existing lines. It requires only a small investment and pays off quickly, thanks to immediate and measurable savings in raw material consumption.

Numbers that speak for themselves (for an average spinning mill with one blow room line*)

- Up to 160 tons of raw material saved per year*

- Annual savings of €288,000*

- Small investment: quick return on investment through immediate and measurable raw material savings.

* Calculation based on a line production of 1,000 kg/h, 90 % efficiency rate, annual production of 8,000 tons, and raw material costs of €1.80/kg (cotton).

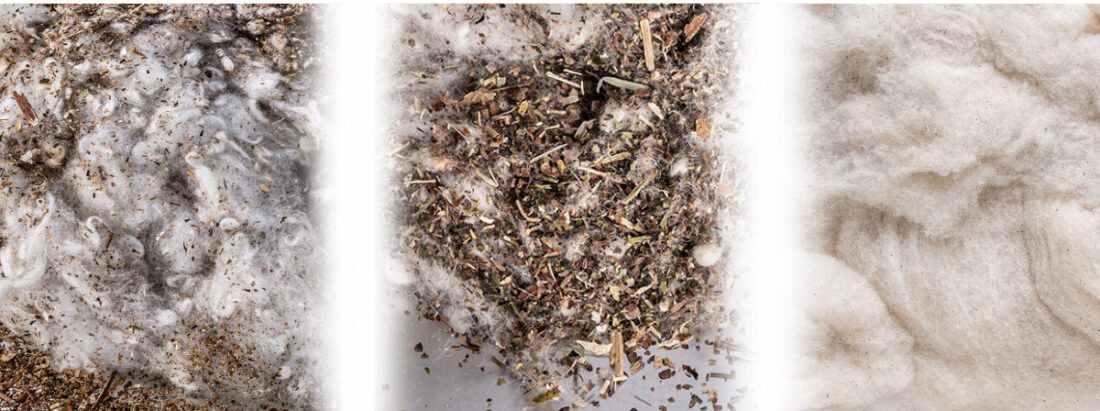

From waste to value: Good fibers recovered, impurities removed.

A small investment with a big sustainability impact

By recovering fibers that were once discarded, mills can reduce raw material consumption, boost efficiency and sustainability and achieve significant cost savings. The Trützschler Online Fiber Recovery Line makes this possible with a solution that is easy to implement, fast to pay off, and proven to deliver very good results.