It’s hard to find skilled operators for spinning mills in Vietnam. Rapid industrialization is creating competition for young talents and many workers choose roles in other industries. Customer Tra Ly Hung Yen has found a partner in Trützschler to help mitigate the effects of this labor shortage and enable successful operations.

Traditionally, yarn manufacturers need many experienced and qualified workers. However, it is difficult to attract and retain these operators. In addition, raw material fluctuations add extra challenges for all spinners. In order to produce yarn with consistent quality, it is necessary to make precise adjustments to the processing system – and this requires trained employees. A major headache for businesses in quality-driven markets like Vietnam!

Tra Ly is one of those businesses. The company’s success is built on a longstanding reputation for quality, so labor shortages generated a potential threat to its future. The family-owned company mainly produces carded and combed cotton (Ne 20 to Ne 40) through standard and compact spinning methods. It has a production capacity of 60 tons per day, with half of that output exported to China, Pakistan or Bangladesh. To find a solution to its labor shortage, the Tra Ly team contacted its trusted partners at Trützschler.

The answer from Trützschler: Highly automated, self-optimizing machinery that helps to maintain consistent quality – even when processing raw materials of varying qualities. This reduces the need for manual intervention. As Do Thi Lan Phuong, Director of Tra Ly, points out: “Innovations from Trützschler offer efficient handling that frees up time for our employees. In this way, we are able to cope with labor shortages. These machines enable higher productivity, improved sliver evenness and more energy-efficient manufacturing. And working together with Trützschler is always a great experience because of their deep expertise, can-do attitude and positive energy.”

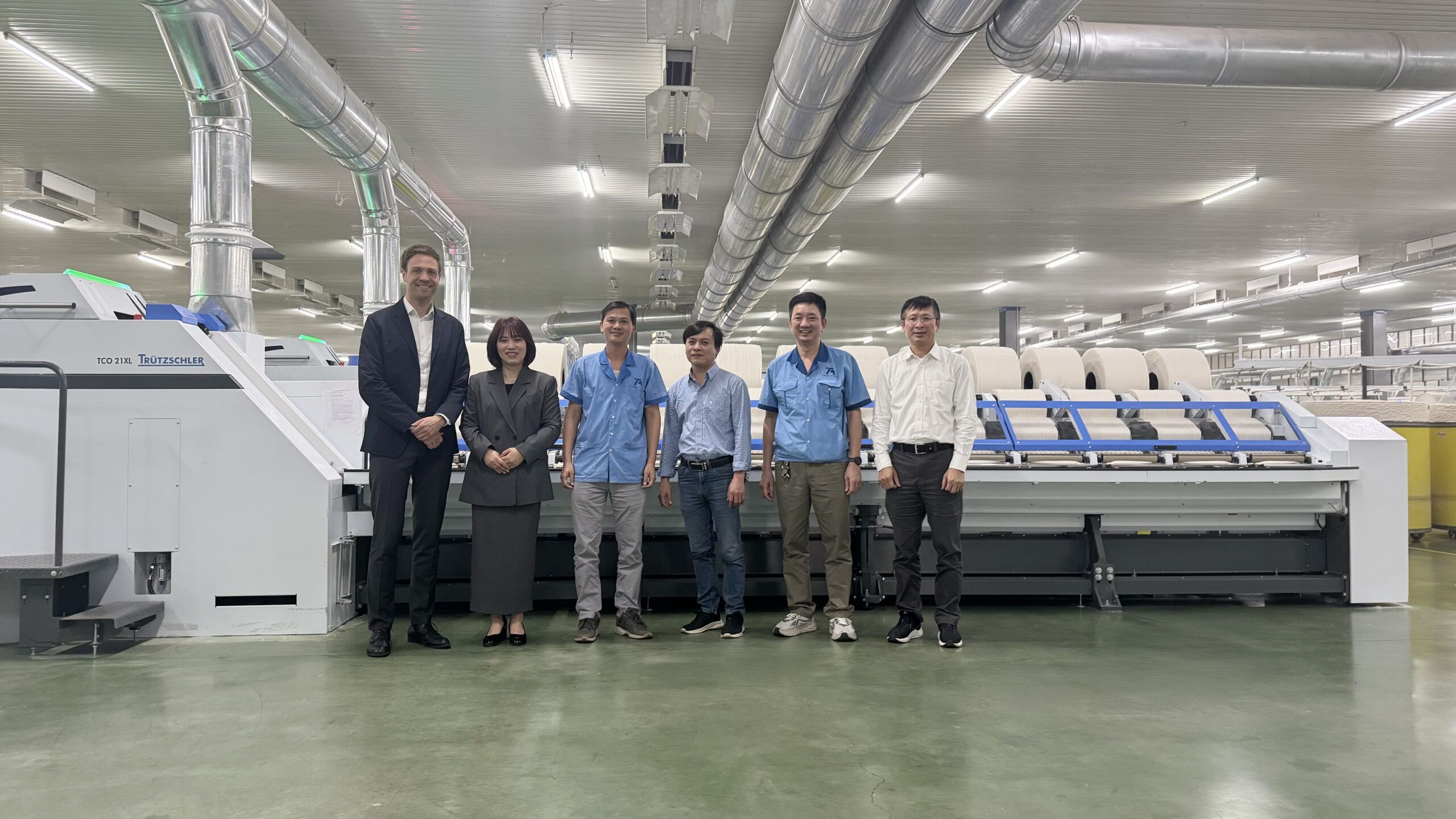

Trützschler’s technical experts are helping Tra Ly to improve its production processes and settings.

Automatized and optimized

Tra Ly now operates the following advanced technologies from Trützschler:

T-SCAN TS-T5: High-quality foreign part separation

This foreign part separator uses state-of-the-art sensors and image-processing technology to detect foreign parts like stems, leaf fragments or other waste – and then automatically ejects them to minimize fiber loss. The highly efficient machine is also easy to clean and maintain, even when production is running.

The intelligent card TC 19i with T-GO

Tra Ly is also benefiting from the TC 19i with T-GO, which is the world’s only proven automatic gap optimizer for carding machines. It increases quality and flexibility by self-adjusting to ensure the best possible carding gap settings in real time, even when raw materials or other production conditions fluctuate.

Autoleveller Draw Frame TD-10

Automated functions like AUTO DRAFT and OPTI SET enable this draw frame to ensure excellent yarn quality by self-optimizing the break draft and drafting point in real time. These innovations help machine operators to adapt settings for various raw material types.

Boosting productivity: The 12-head comber TCO 21XL

This machine increases productivity by about 50% because it operates 12 heads instead of a typical eight head setup, while delivering the same excellent quality. Features like COUNT MONITORING perform automatic checks on sliver count variations from a given limit, thus contributing to consistent quality.

Local expertise and fast support

Trützschler’s local team of technical experts, along with its well-stocked spare parts inventory and repair facilities in Vietnam, ensure that Tra Ly maintains high levels of productivity with reliable quality. This expert team provides fast responses based on indepth knowledge. As a result, Tra Ly can rely on outstanding customer service – and downtime is kept to a minimum. The team from Trützschler is even available to suggest process improvements and potential digital optimizations.

Traly operates numerous Trützschler carding machines. Recently, the TC 19i completed Tra Ly’s portfolio.

Fit for the future

Tra Ly recently installed My Mill, Trützschler’s mill monitoring system. Based on real-time data from My Mill, Trützschler experts can conduct digital audits to provide on-site guidance, training and troubleshooting. Trützschler is looking forward to continuing to support Tra Ly. The Vietnamese company is excited about the ongoing collaboration, too. “Working together with Trützschler is always a great experience because of their deep expertise, can-do attitude, and positive energy,” says Do Thi Lan Phuong, Director of Tra Ly.

Cover picture shows: From left to right: Benjamin Mund (Regional Sales Manager at Trützschler), Do Thi Lan Phuong (Director of Tra Ly), Nguyen Van Trai (Equipment Coordinator at Tra Ly), Nguyen Van Binh (Trützschler Technician), Do Manh Nhan (Mill Manager) and Dinh Van Loi (Trützschler Sales Agent).