The Trützschler headquarters in Mönchengladbach has gained one more “employee”: The first Robolink articulated arm robot has made its way into the in-house training workshop – a gift from the Cologne-based motion plastics* expert Igus. The company’s managing director Frank Blase and Alexander Mühlens, Head of business unit Low Cost Automation at Igus, personally handed over the so-called low cost automation robot arm to Trützschler. It is intended for use in the training program.

The two family-owned companies from the Rhineland can already look back on a partnership spanning several decades. Igus primarily supplies Trützschler in the field of energy chains. Shareholder Dr. Michael Schürenkrämer sees the articulated arm robot as a great opportunity to introduce his apprentices to the important topic of “automation in industry” at an early stage: “The automation and optimization of a wide variety of processes is something Trützschler has always stood for. As early as the 1970s, we used the first welding robot in North Rhine-Westphalia. We strive to offer our apprentices an innovative training program that focuses on these topics. We are therefore more than pleased about this gesture by our partner Igus,” says Dr. Schürenkrämer.

F.l.t.r.: Rene Haas, Instructor Industrial Apprenticeship at Trützschler, Igus CEO Frank Blase, Trützschler shareholder Dr. Michael Schürenkrämer & Florian Schürenkrämer, member of the Shareholders’ Committee

“Tech up, cost down” – this is how the low cost automation solutions work

Low cost automation solutions like the Robolink achieve a significant increase in productivity with the help of simple and affordable automation in the form of robotic components. Monotonous tasks, such as sorting components, can thus become independent and employees can be used for more demanding tasks. This leads to an increase in efficiency.

“In principle, our applications are characterized by two special features: A low entry price by relying on high-performance plastics that are both durable and cost-effective, and an easy operation. It is a great added value that unskilled persons sometimes only need up to 30 minutes to program the robotic arm,” says Igus Managing Director Frank Blase. For this purpose, the robot arm has a kind of joystick, for example, which can be used to train certain motion sequences. The Robolink has already proven itself in various industries, for example as a fully automated drink dispensing system or as an assembly robot.

Alexander Mühlens, Head of Low Cost Automation at Igus (r), gives insights into the Robolink system.

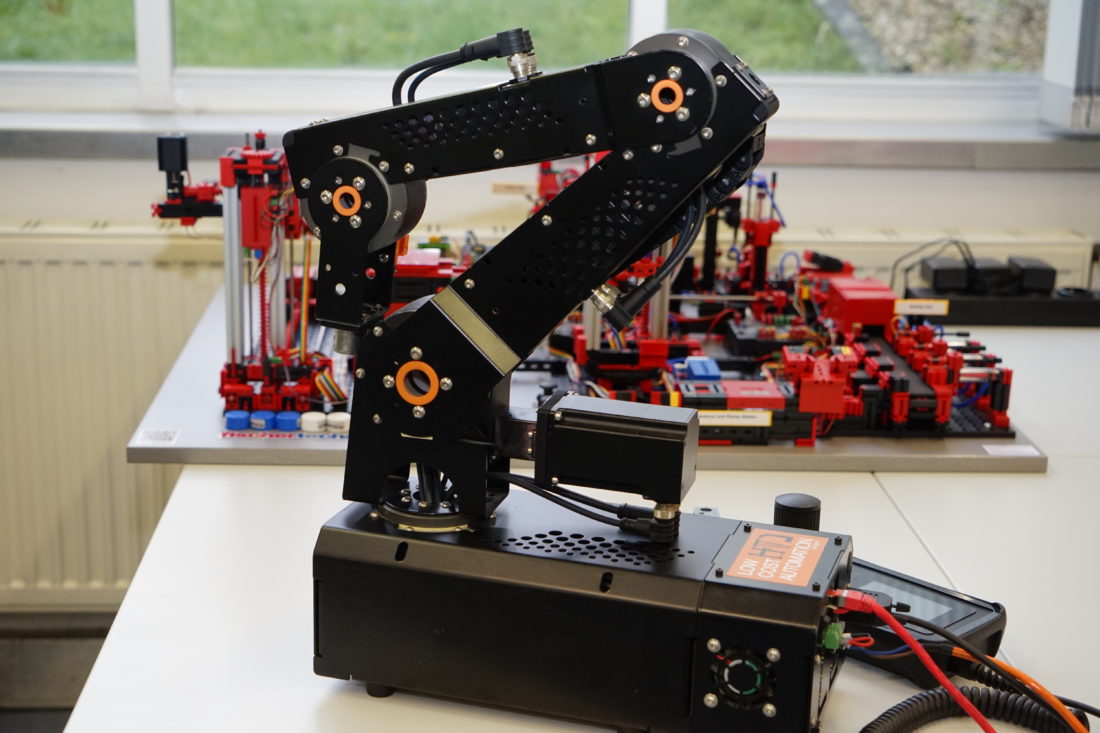

the low cost automation robot Robolink

“We sincerely thank Igus for its support and look forward to the next successful years of cooperation,” says Dr. Schürenkrämer, summing up the project.

*Motion Plastics = Products for motion made from low-wear, high-performance polymers.