The compulsory wearing of masks currently dominates the public space. However, an effective protective measure in times of COVID-19 has almost dropped out of sight: The disinfection of our hands.

Our hands are everywhere: On door handles, shopping cart handles and handrails in public transportation. And, not to forget, our faces. People touch their own face over a dozen times an hour. It usually happens unknowingly, for instance to scratch, brush away a strand of hair or adjust glasses. This makes it easy for pathogens to get into the mouth, nose or eyes. All doctors recommend therefore the increased, intensive washing of hands. But when there is no water, there is no washing of hands. Fortunately, there are wet wipes and special disinfectant wipes available.

Wet wipes and disinfectant wipes – the solution when on the go

Cleaning wipes for single use are available as dry wipes or as wet wipes with lotion. In the past, these products used to be simply practical, but now – in Corona times – they are indispensable, for example when commuting or shopping. The basis of all cleaning wipes are nonwovens. The majority of commercially available products are made of hydroentangled fiber material. The main advantage of hydroentangled, light-weight nonwovens is that they can be produced quickly and in large quantities. Production speeds of 250 m/min and more are easily achieved. The nominal capacity of a spunlace line is just under 2.5 tonnes per hour, based on 50 grams of web weight per square metre, 250 m/min at the winder and the typical 3,800 mm working width. These 2.5 tonnes of material correspond to almost 50,000 square metres of nonwoven. That is a huge amount of wipes per hour, enough to cover seven football fields. Since such large quantities can be produced in a highly automated process in one step, the pure conversion costs are low. A blend of polyester and viscose fibers is used for wet wipes and disinfectant wipes. The use of polyester makes the nonwoven soft and viscose makes it absorbent.

Spunlace lines for hydroentangled cleaning wipes

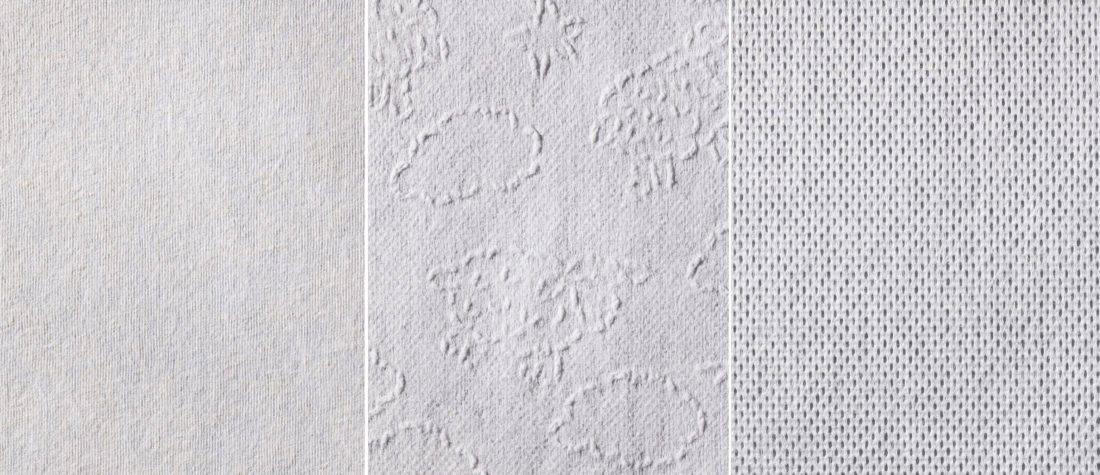

First, fiber bales are opened in bale openers and dosed and mixed in the desired ratio. In high-speed lines, two roller cards connected in series separate the fibers gently and evenly, forming a homogeneous fiber mat. In the next step, high-pressure water jets “knot” the fibers together so that the desired tensile strength and puncture resistance is achieved and no individual fibers come loose during use. A further advantage of hydroentangling is that not only smooth products but also a wide variety of perforated and structured nonwovens can be produced inline. The water jets not only knot the fibers, they also move them. Special shells for structuring or perforation have embossed patterns or soldered-on protrusions. When they are pulled up, fibers settle mainly in depressions. Correspondingly fewer or no fibers are found on protruding areas. This results in structural patterns or holes.

Infinite variety: hydroentangled nonwovens

The nonwovens are dried and can already be cut to the desired width during winding. At the end of a Truetzschler line, there are either large rolls or convertible narrow rolls. Wet wipes are produced in a separate, subsequent conversion process. The nonwoven web is cut crosswise, folded, impregnated with a water or oil-based lotion, and then packed. If the lotion has an antibacterial or even antiviral effect, we speak of disinfectant wipes. While disinfectant wipes were already a practical companion before Corona, they are indispensable today.

Truetzschler Nonwovens has been successfully selling spunlace lines for almost 25 years. Especially in the current situation, customers from all over the world benefit from the high production speeds of Truetzschler lines to cover the rapidly increasing demand for disinfectant wipes and to make an effective contribution to contain the pandemic. Manufacturers are also well prepared for the time after Corona: Instead of disinfectant wipes, the nonwoven material can also be used for baby- or bodywipes too – it’s the lotion which makes the difference.

Aquajet – the core of a Truetzschler spunlace line